The Suspension’s Role in Truck and Driver Performance

Vocational trucks are an important part of many industries, the transport and logistics industry most of all. A truck’s suspension system is pivotal for performance, safety and driver comfort. The most important role of any suspension is to provide positive control of an axle’s position and movement and the requisite roll stability. However, a suspension is also necessary for supporting the vertical load and isolating the occupants and equipment from road inputs. Dive deep into the geometry of suspensions, its impact on driver well-being and vehicle performance, and its implications for the future of commercial transportation.

Diving Into Suspension Geometry

The two most basic categories of suspension geometry are torque-reactive and non-torque-reactive. The distinction between these systems goes beyond mere technical jargon; it’s at the heart of suspension design and performance.

Torque-Reactive Systems: As vehicles move and generate torque, the suspension system’s reaction to this force becomes a critical consideration. Systems that respond to this torque can generate forces that may influence the vehicle’s stability and handling, especially when not appropriately managed.

Non-Torque-Reactive Systems: Offering an alternative to the limitations of torque-reactive suspensions, these non-torque-reactive systems are crafted to remain essentially unaffected by drivetrain forces, promising consistent performance across varied driving conditions.

The choice between these solutions isn’t binary. It’s a nuanced decision that involves analyzing specific application demands, from the vehicle’s operational environment to its typical load. Depending on the circumstances, both types of approach can provide any given vehicle with an adequate suspension. However, a non-torque-reactive suspension will provide the most comfort for a driver and the highest level of equipment protection.

Overreaction

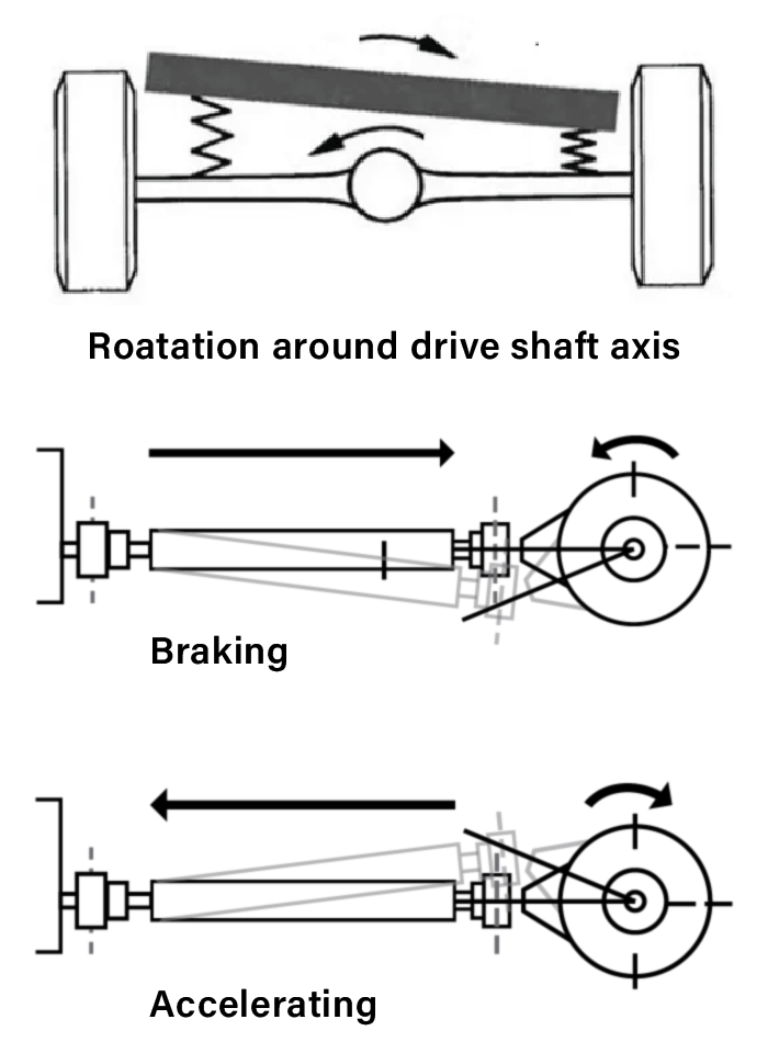

A torque-reactive suspension will exhibit a vertical response during all braking and acceleration events. For example, if a vehicle is equipped with a torque reactive front suspension, the front of the vehicle will drop down when the brakes are applied. The more aggressive the braking event is, the more pronounced the dropping experience will be for the driver. This event is commonly referred to as brake dive.

If the vehicle has a torque-reactive rear suspension, then the rear will drop during braking as well, and will also raise during acceleration events. One can observe this reaction when tractors or trucks are coming up to speed on the road, as they will raise up and then drop down as the driver shifts gears.

The physical strain of dropping and rising can not only cause wear and tear on all driveline components, including bushings and U-joints, but will also cause the driver to pitch forward and back in their seat. If a fleet’s application has a higher percentage of starts and stops during maneuvering, or if aggressive driving is often necessary, it should shy away from a torque-reactive suspension geometry.

Analyzing Roll Stability, Ride Quality, & Traction

However, the performance of any suspension system isn’t judged solely by its ability to handle loads. The triad of roll stability, ride quality, and traction offers a comprehensive lens to evaluate the efficiency of the technology in place.

Roll Stability

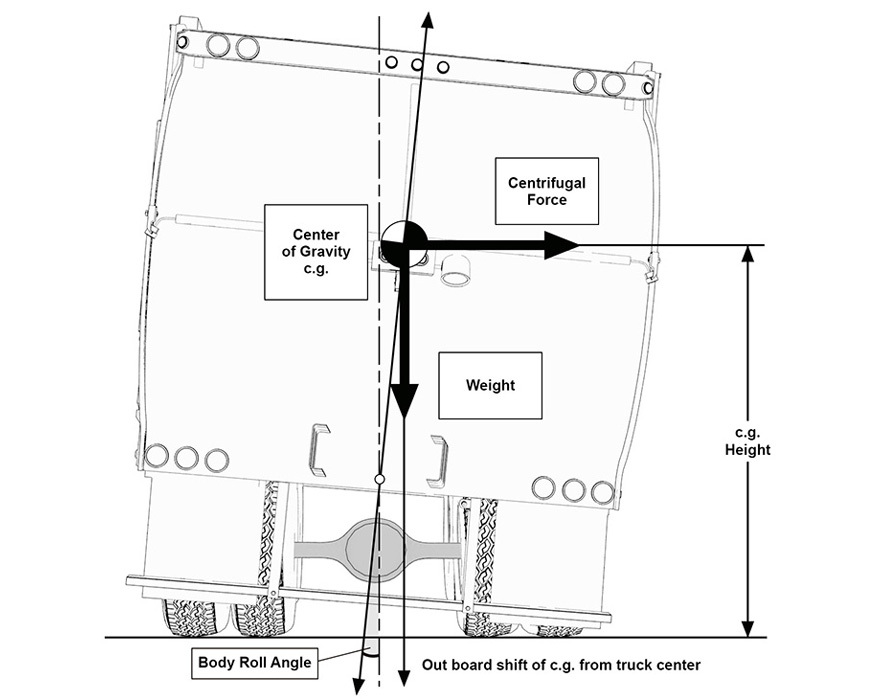

The ability of a vehicle’s center of gravity to resist straying from the vehicle’s centerline, when subjected to lateral acceleration is termed roll stability. A superior suspension system effectively counteracts forces that could tip the vehicle, maintaining a stable orientation. The ability to maintain stability becomes crucial, especially in vocational trucks, where the loads can be heavy and unevenly distributed. Torque-reactive systems, while efficient, can occasionally pose challenges with drivetrain forces potentially destabilizing the vehicle.

Traction

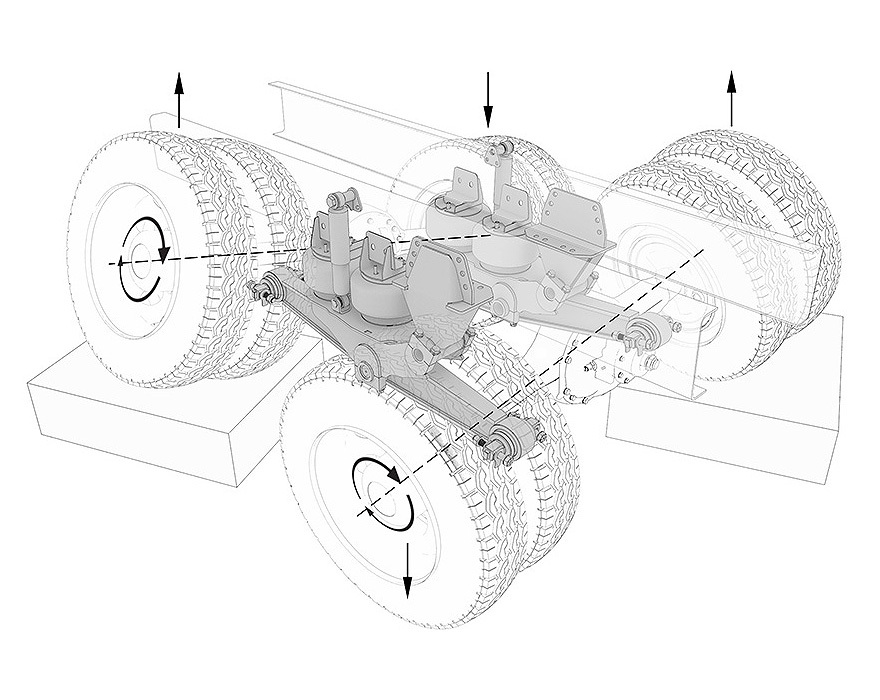

The transmission of engine power to the road is mediated by the vehicle’s traction. Superior traction ensures that power isn’t wasted while offering better control, especially on challenging terrains. Suspensions play a pivotal role in traction, maintaining tire-road contact. Walking beam suspensions, particularly, showcase tangible advantages. The walking beam ensures that as one tire navigates a bump or depression, its counterpart on the other end compensates, maintaining consistent ground contact.

Ride Quality

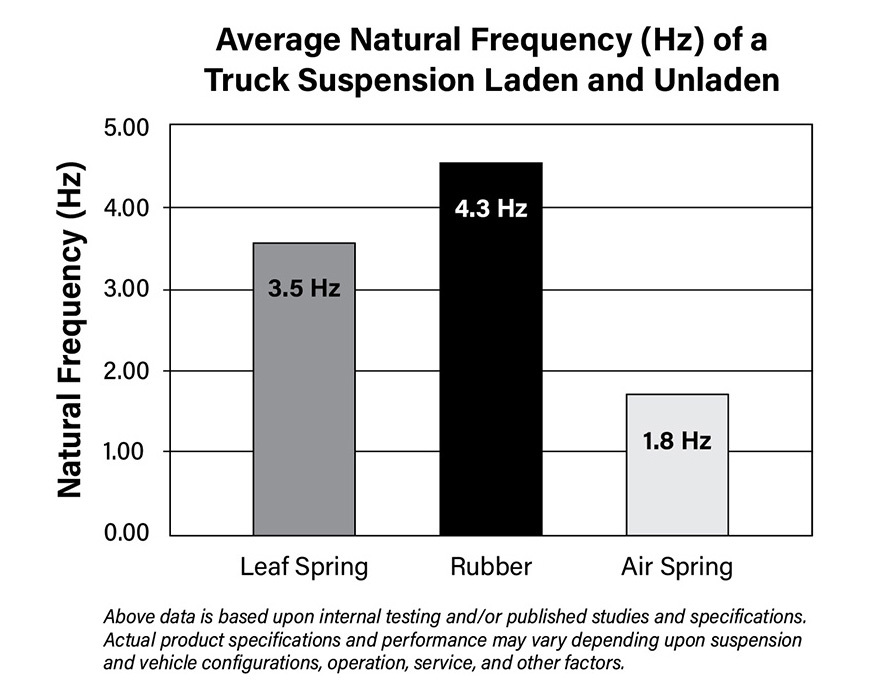

Beyond mere technical metrics, the human element cannot be ignored. Drivers spend prolonged hours in their vehicles, and thus the suspension system directly influences their comfort. A smoother ride reduces fatigue, increases productivity, and lowers long-term health risks. Air springs, with their adaptive nature, score high on this front. Their ability to adjust to different loads ensures that the vehicle’s ride remains fairly consistent, irrespective of its weight. Suspensions with lower natural frequencies isolate the chassis and driver from road inputs to improve ride comfort. Vocational vehicles normally suffer from high levels of vertical vibration. A spring or rubber suspension may amplify vibration in the low frequency range, affecting ride comfort.

The Convergence of Comfort, Control, & Cost-Efficiency

Driver comfort isn’t merely about a smooth ride—it directly affects performance, fatigue levels, and even long-term health implications for vocational truck operators. One of the pivotal advancements in heavy-duty truck suspension technology is its increasing ability to couple control and stability with ride comfort, ensuring that the driver’s health and the vehicle’s performance are in equilibrium.

Driver Well-Being

Constant exposure to vibrations and jolts not only leads to immediate discomfort but can also cause long-term health complications. Issues such as back pain, joint ailments, and fatigue can arise from prolonged exposure to harsh riding conditions. Modern suspension systems, especially the air ride variants, incorporate technologies to reduce these vibrations, ensuring that the driver remains comfortable, alert, and safe.

Vehicle Control

A well-specified suspension also adds to a driver’s control, especially in demanding situations. Whether navigating a tricky bend, carrying a delicate load, or managing wet and slippery conditions, the right suspension system can offer the control needed to ensure precision and safety. This is where the torque-reactive vs. non-torque-reactive debate comes into play.

Cost-Efficiency

While it’s tempting to think of the suspension system purely from a performance standpoint, its economic implications are profound. The right suspension can reduce the wear and tear on other components, including the tires and chassis. Over time, this translates to lower maintenance costs, fewer breakdowns, and extended vehicle life. Moreover, improved driver comfort can lead to reduced medical expenses and absenteeism, further enhancing operational cost-efficiency.

Concluding Thoughts On The Path Forward

As the commercial transportation landscape evolves, so do the demands on the vehicles that power it. The role of suspension in a truck’s overall performance and driver’s well-being cannot be understated. With advancements in technology, the opportunity to boost not just the performance but also the economic viability of a fleet is tangible. When a driver is comfortable for the ride, they can operate safer and longer, in a cost-effective vehicle that supports a fleet’s journey for years to come.

Blog Author

Mark Molitor

Senior Product Manager - Chassis Suspensions