Purpose Built for First Responders

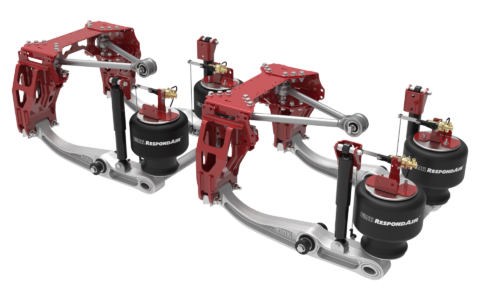

Developed specifically for fire and rescue vehicle applications, RespondAir® is the first non-torque reactive suspension rated from 30,000 to 35,000-pound capacities. RespondAir® directly addresses the most pressing needs with heavy-duty fire apparatus applications. The suspension is equipped with severe-duty bushings, high-strength cast components, seamless tubing, and migratory self-healing coating to provide maximum durability under extreme duty cycles.

Engineered with a non-torque-reactive design, the heavy-duty rear air suspension increases stability and removes unwanted chassis movement during braking and acceleration. The configuration minimizes axle movement and reduces stress on driveline components and vehicle occupants. A V-Rod configuration provides superior lateral stability and reduced tail swing - especially critical for aerial apparatuses with extended overhangs. Integrated proven 500 Series height control valves offer the highest flow rates available for optimal leveling performance. The air suspension system also features a rapid air-dump function that allows fire trucks to reduce their overall height, enabling access to older station houses with lower door clearances.

RespondAir® is engineered for both single axle (30k-35k) and tandem axle (60k-70k) configurations, making it ideal for aerial trucks, rescue pumpers, tankers and other heavy-duty fire apparatus vehicles. The RespondAir® is backed by an industry-leading 5-year warranty on structural components. The system will be available through OEM partners beginning late 2025.

Features

-

![RespondAir's non-torque reactive design]()

Non-Torque Reactive Design

The configuration minimizes suspension windup, frame rise, and torsion into the axle connection while increasing roll stiffness and reducing roll steer for maximized stability.

-

![V-rod on the RespondAir]()

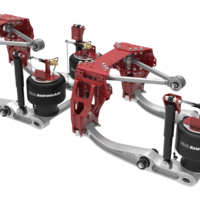

V-Rod Configuration

The unique V-Rod Configuration controls axle movement and resists unwanted rolling motion to provide uniform roll stability while reducing truck tail wag.

-

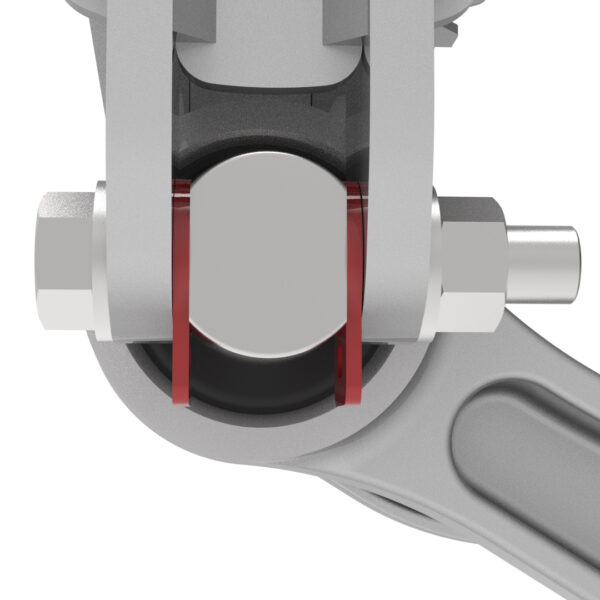

![Three bushing types used on the RespondAir]()

Severe Duty Bushings

Large, severe duty rubber bushings reduce the stress the rubber experiences, diminishing maintenance requirements and extending service life.

-

![Dual 500 Series height control valves on RespondAir]()

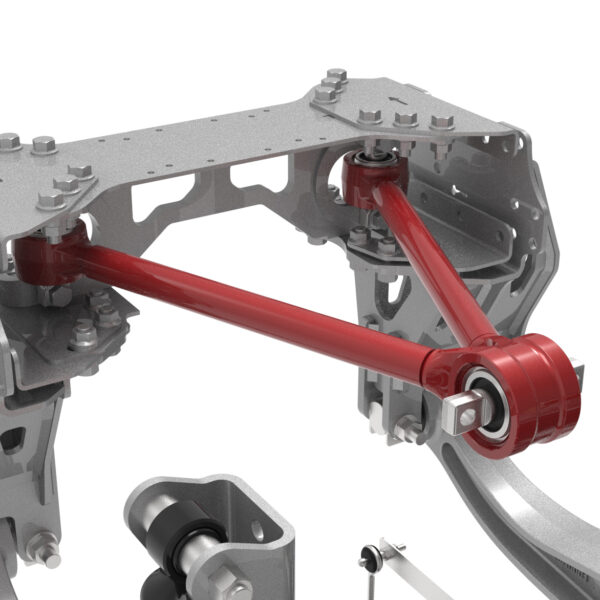

High Flow Height Control Valves

Dual 500 series height control valves balance the chassis to allow the suspension to react quickly to uneven load and maintain proper ride height during high-speed maneuvers.

-

![A rendering of RespondAir with the beams highlighted in red.]()

Cast Structural Beams

The beams utilize premium high strength steel for durability and reliability. The seamless high strength steel torsion tube provides optimized roll stability.

-

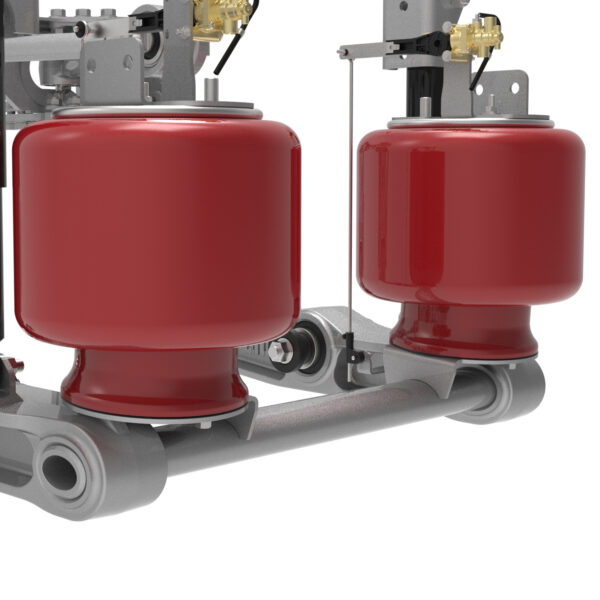

![Air Bags on the RespondAir]()

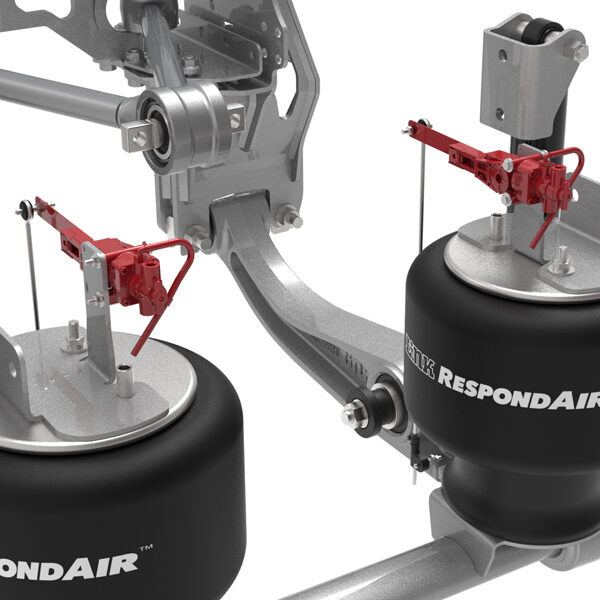

Large Volume Air Springs

Air springs isolate the chassis structure from excessive vibrations and impacts of the road for optimal protection to critical life-saving equipment and costly aerial components.

-

![Responsive shocks on the RespondAir Suspension.]()

Shock Absorbers

The shock absorbers are tuned for optimal ride characteristics and protect the rear air springs from overextension when the outriggers are used.

-

![Shims for RespondAir bushings]()

Robust Shimmed Alignment

Shimmed alignment provides accurate and maintained axle alignment that will not loosen with vibration or high impact loads.

-

![Fire Apparatus Manufacturers' Association]()

Member of FAMA

Link is a certified member in good standing with the Fire Apparatus Manufacturers' Association.

Videos

Specifications

Select model:

| RA-SA-30 | |

|---|---|

| Axle Specs | SINGLE |

| Ride Height | 8-15.5 in |

| Axle Spread (Min) | N/A |

| Axle Spread (Max) | N/A |

| Capacity | 30,000 lbs |

| RA-SA-35 | |

|---|---|

| Axle Specs | SINGLE |

| Ride Height | 8-15.5 in |

| Axle Spread (Min) | N/A |

| Axle Spread (Max) | N/A |

| Capacity | 35,000 lbs |

| RA-TA-60 | |

|---|---|

| Axle Specs | TANDEM |

| Ride Height | 8-15.5 in |

| Axle Spread (Min) | 57 in |

| Axle Spread (Max) | 72.5 in |

| Capacity | 60,000 lbs |

| RA-TA-70 | |

|---|---|

| Axle Specs | TANDEM |

| Ride Height | 8-15.5 in |

| Axle Spread (Min) | 57 in |

| Axle Spread (Max) | 72.5 in |

| Capacity | 70,000 lbs |

| Axle Specs | Ride Height | Axle Spread (Min) | Axle Spread (Max) | Capacity | |

|---|---|---|---|---|---|

| RA-SA-30 | SINGLE | 8-15.5 in | N/A | N/A | 30,000 lbs |

| RA-SA-35 | SINGLE | 8-15.5 in | N/A | N/A | 35,000 lbs |

| RA-TA-60 | TANDEM | 8-15.5 in | 57 in | 72.5 in | 60,000 lbs |

| RA-TA-70 | TANDEM | 8-15.5 in | 57 in | 72.5 in | 70,000 lbs |

Related Products

Air Link® Redline

The Air Link® tandem drive axle suspension is a unique combination of air spring over walking beam technology. It delivers everything you demand in an emergency vehicle suspension — high roll stability, low maintenance and a smooth ride. The unique design also ensures maximum traction and load equalization. The distinctive Air Link® design provides optimum ride height and on or off highway performance.