Link Engineering – The Process Behind the Products

When most people think of Link, they picture suspensions, suspension controls, or one of our specialty products. What often goes unseen is the engineering effort behind every product. Our team of more than 50 engineers, designers, and drafters works across the full product lifecycle: concept, analysis, design, simulation, validation, and continuous improvement. Every product that reaches our customers has been through a disciplined process of modeling, testing, and confirmation to ensure it performs in the field and meets Link’s high-quality standards.

Product Engineering

Every Link product starts with a problem worth solving—whether to improve safety, reduce fatigue, or increase operator efficiency in the trucking and transportation industries. Once a project is defined, our engineers apply modern design and simulation tools to evaluate concepts early in the product lifecycle process. By evaluating concepts before prototypes are built, we reduce cost, shorten development time, and eliminate unnecessary iterations.

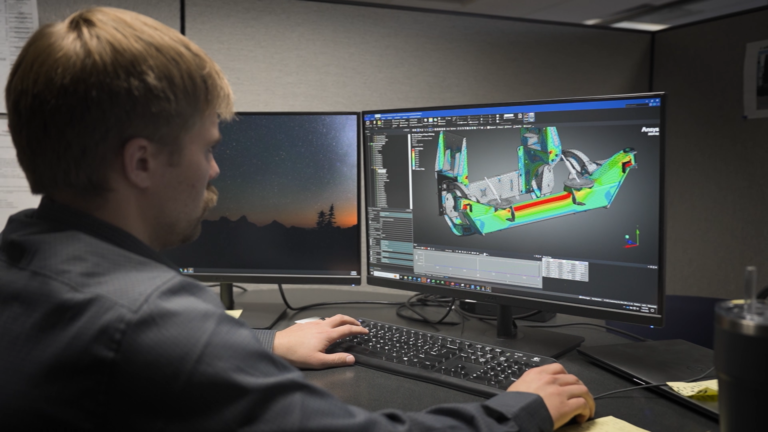

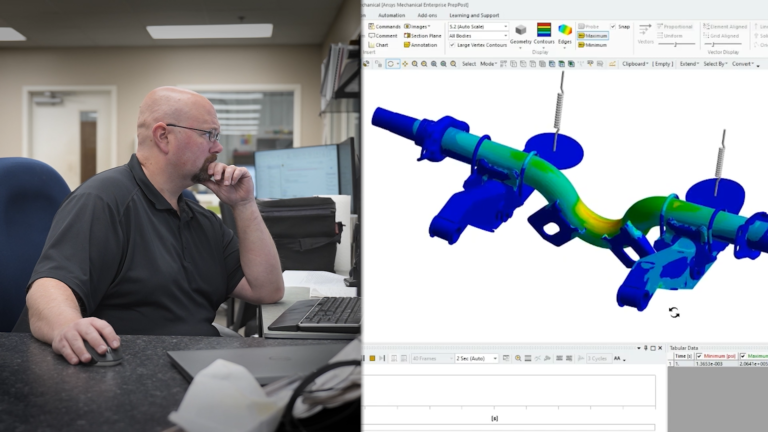

Our engineering environment includes Creo, SolidWorks, and Windchill for 3D modeling and lifecycle management, as well as Matlab/Simulink/SimScape for model-based design, system simulation, and algorithm development. These tools allow us to integrate mechanical, electrical, and control system design into a unified development process.

Simulation is central to our workflow. Finite element analysis (FEA) is used to reduce mass without compromising strength or fatigue life. Welded joints and metallic structures are analyzed for durability under vibration, load cycling, and impact. Kinematic and compliance models support suspension geometry optimization, while dynamic simulations help tune ride characteristics and predict component loads. FEA ensures prototypes perform as expected, with fewer surprises during validation.

Applied Technologies Center (ATC)

Once prototypes are ready, we transition the product to validation in our Applied Technologies Center (ATC) in Sioux Center, IA. The ATC is a 10,000-square-foot lab equipped with MTS servo-hydraulic actuators on a 360-ton inertial mass bedplate, capable of applying up to 55,000 lbs. per channel. This enables both component level and full system-level testing under representative conditions.

Our testing program includes:

- NVH Analysis – Using accelerometers and other instrumentation to quantify ride quality and isolate sources of vibration and noise.

- Vibration Testing – Simulation of real-world road profiles to evaluate durability and vibration isolation, based on nearly 50 years of compiled road testing.

- Durability Testing – Multi-axis load input to verify suspensions and components meet or exceed OEM specifications and life targets.

- Virtual/Physical Correlation – Closing the loop between FEA, fatigue models, and physical test data.

- Ride & Handling Evaluation – Combining lab data with on-road and track evaluations, including use of our 6-axis cab ride simulator.

The goal of the ATC engineers is simple: confirm that our products not only meet theoretical design requirements but also deliver long service life in real-world environments.

Suspension Controls Engineering

Our Suspension Controls Engineering Center in Grand Rapids, MI, focuses on mechanical and electronic height control systems. This team develops both pneumatic and electronic valve technologies, applying expertise in fluid dynamics, embedded electronics, and software. Onsite facilities allow airflow and leak testing, environmental and submersion testing, material validation, and valve lifecycle durability assessments. This ensures our controls meet the same standards for reliability and performance as our suspension systems for Link’s customers and partners.

Collaborative Engineering

Beyond our own product portfolio, we collaborate with OEM engineering teams to accelerate their development cycles. Link brings years of experience tailoring solutions to meet the rigorous demands of today’s various markets. Our engineering teams provide modeling, simulation, and validation expertise that can be integrated into customer projects, extending their in-house capacity. Link’s collaborative engineering approach delivers performance, enhances installation efficiency, leads the industry in capacity range, and improves overall driver well-being. Our helps our partners reduce risk and bring robust products to market faster.

Conclusion

For more than four decades, Link has advanced suspension and control technologies for commercial vehicles. Our engineering process integrates modern CAD/CAE tools, advanced simulation, and comprehensive validation testing to ensure durable, efficient, and cost-effective products. The result is equipment that improves safety, reduces downtime, and enhances operator well-being. It’s our promise to provide great products, superior service, outstanding product quality, and on-time delivery to every customer.

Blog Author

Greg Hulstein

Vice President of Engineering